HOW IT'S MADE MATTERS

Sroka’s manufacturing operations provide complete systems engineering, project management, precision machining, welding and fabrication, product assembly, testing and paint finishing capabilities.

Sroka is headquarted in Strongsville, Ohio, a southwest suburb of Cleveland. Our 64,000 sqft (≈6.000 m²) manufacturing facility incorporates over 100 machines and dedicated equipment in support of our complete operation.

ENGINEERING

At the heart of our operation, engineers are involved at every level of the organization. It’s what sets us apart. From management to sales and production to support. Engineering has been ingrained into the business since the first day of operation. As a result, industry best practices are utilized with every opportunity and provided to the benefit of our clients.

PROJECT MANAGEMENT

Each project is handled with care from the first moment of inquiry. We embrace open communication and strive to deliver the absolute best products possible.

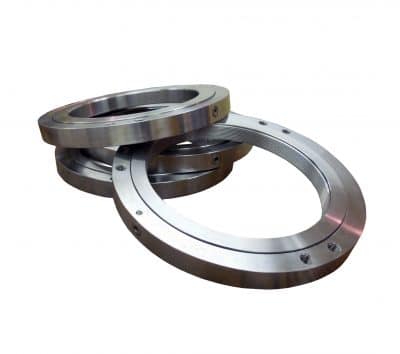

PRECISION MACHINING

Our facilities boast a fully equipped CNC department along with over 100 supporting machines. Whether it is turning, milling, cutting, broaching, boring, gear-shaping, or tapping, we are prepared to machine a vast variety of parts from very small to very large.

WELDING & FABRICATION

This is where we join various metals to create unique products. The process starts with our automatic saws and precision CNC plasma cutting machine. Once the parts are cut, formed, and machined, they are ready to be welded. Weld fixtures and dedicated weld tables are utilized to ensure accuracy and repeatability.

COMPONENT MANUFACTURING

To manufacture larger complex machines, many smaller components need to be produced. We specialize in producing mechanical components, hydraulic cylinders, hydraulic hoses, masts, carriages, and even transmissions for our material handling equipment.

ASSEMBLY

At this stage, everything comes together. Each chassis is mated with mechanical, electrical, and hydraulic systems. Our technicians take pride in their work and attention to detail is most important to make our products easy to operate and maintenance-friendly.

TESTING

Every unit is tested to ensure quality and performance. This is where adjustments may be made because we want you to love our product, period.

PAINT & FINISHING

Every unit is primed and painted using a multi-coat industrial enamel. All sides are coated including the undercarriage. Custom paint colors are available to match your operation.

PARTS & SUPPORT

This is perhaps the most important stage in the life cycle of any product. You need fast support when you need it. Our company is customer-centric, so every call is handled with care and urgency. It’s our goal to ship in-stock parts the same day and to expedite any specialty components through manufacturing to keep you up and running.